The Global Marine Group is pleased to announce the new ownership of the business by Keppel Infrastructure Fund, a fund managed by Keppel.

Contact Us

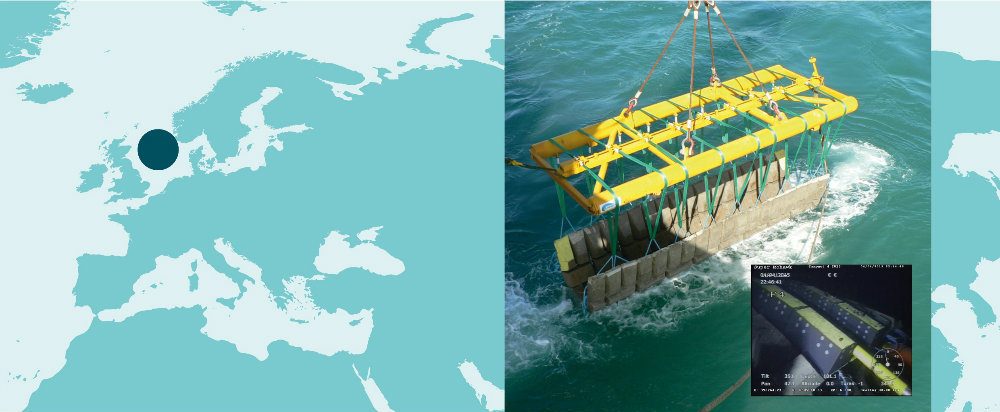

Global Marine have worked successfully with oil & gas client Tampnet over a number of years. This project is the fourth of its kind in a series of critical North Sea installations.

Tampnet operate the largest offshore high-capacity communication network in the world in both the North Sea and the Gulf of Mexico. This project was designed to further enhance high-capacity communications networks in the North Sea, including a platform to platform cable system with four branching units.

Following the successful installation of a prior Tampnet project in 2014, one of Global Marine’s key installation vessels, Cable Innovator, was contracted to complete the work. The project incorporated 74.157 km of fibre optic cable, with a cable spur for the second platform also laid to allow for platform connection at a later date.

The project initially required highly skilled route survey work followed by an innovative solution to install and future-proof pipeline crossings using mattressing.

Cable Innovator, an experienced offshore engineering vessel successfully executed the installation phase of the project operating in close proximity to both pipelines and platforms.

Plough burial was carried out for the whole length of the cable excluding a 9 km stretch passing through a boulder field.

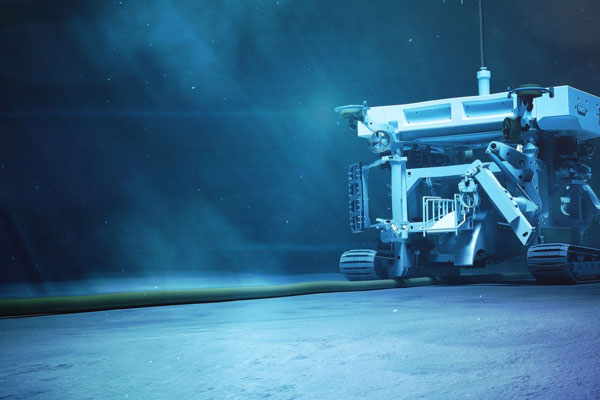

Initially, mattress deployment work was undertaken across various oil and gas pipelines, as well as umbilicals. This was prior to Cable Innovator laying fibre optic cable in the centreline of a channelled mattress on the seabed nearly 120 m below the surface.

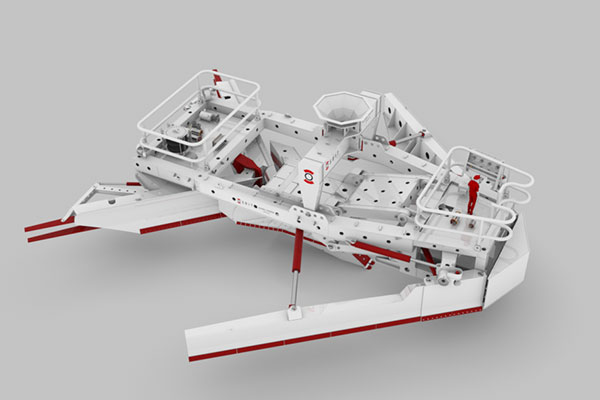

The mattress design has been developed specifically for this project utilising concrete mattresses and combining this with recycled rubber providing greater support to the cable over the pipeline crossings and ensuring the cable is retrievable for future maintenance operations, should this be required. This inventive solution required the extensive capability of Cable Innovator and the Mohawk submersible ROV.

The newly developed Cable Crossing Units (CCU) were developed in conjunction with East Anglian based firm Scour Prevention Systems Limited (SPSL).

The innovative and patented solution used a matrix of end-of-life recycled rubber tyres to remediate and eliminate scour around offshore structures and over cables and pipes, which is recognised as a significant problem within the offshore energy industry.

The approach protects the cable from any unnecessary ‘free-spanning’ of the cable left suspended in open water presenting significant risk of damage due to commercial fishing activities.

We are delighted to introduce SubConnect, the latest addition to GMG’s subsea data and...

We are delighted that our vessel, the Cable Innovator, has successfully completed a cable...

We take immense pride in recognizing the outstanding achievement of our GMG rowing team...

Image of one of the three SMART cable instrumented repeaters on the seabed following...

Big charity challenges are a regular event at Global Marine Group. 2023 was no...

Captain John Tollady from the Cable Retriever, shares his account of a long overdue...

We caught up with our Chief Officer Kaya Teare about life offshore as a...

Our Head of Asia, Sheryl Ong, is going to be presenting at the SubOptic Foundation Symposium to...

Chelmsford, 8 March 2023. Global Marine, a market leader in subsea fibre optic cable...

In recognition of the high standard of weather observations undertaken voluntarily at sea Cable...

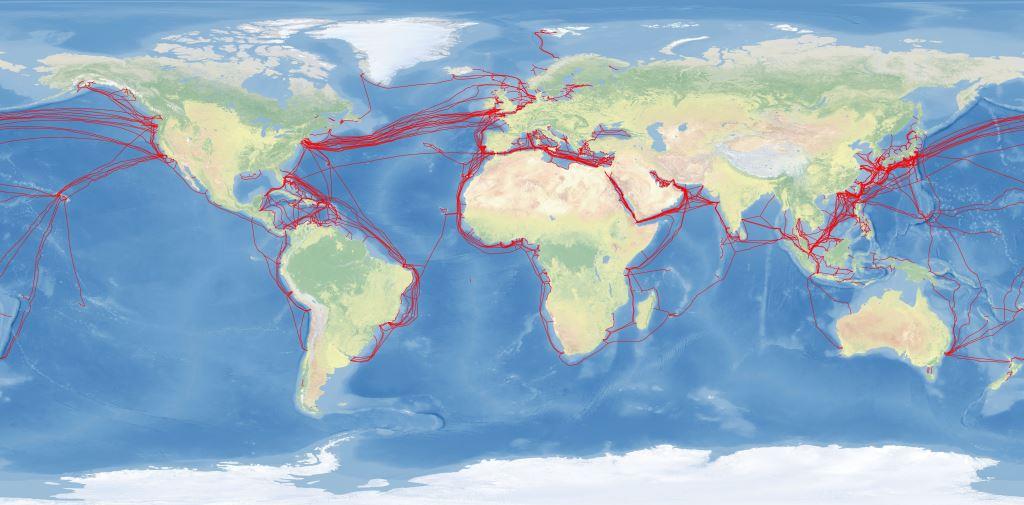

As an independent island nation, the UK is heavily dependent on the uninterrupted provision...

Global Marine has completed the initial subsea fibre-optic cable route survey scope for the...

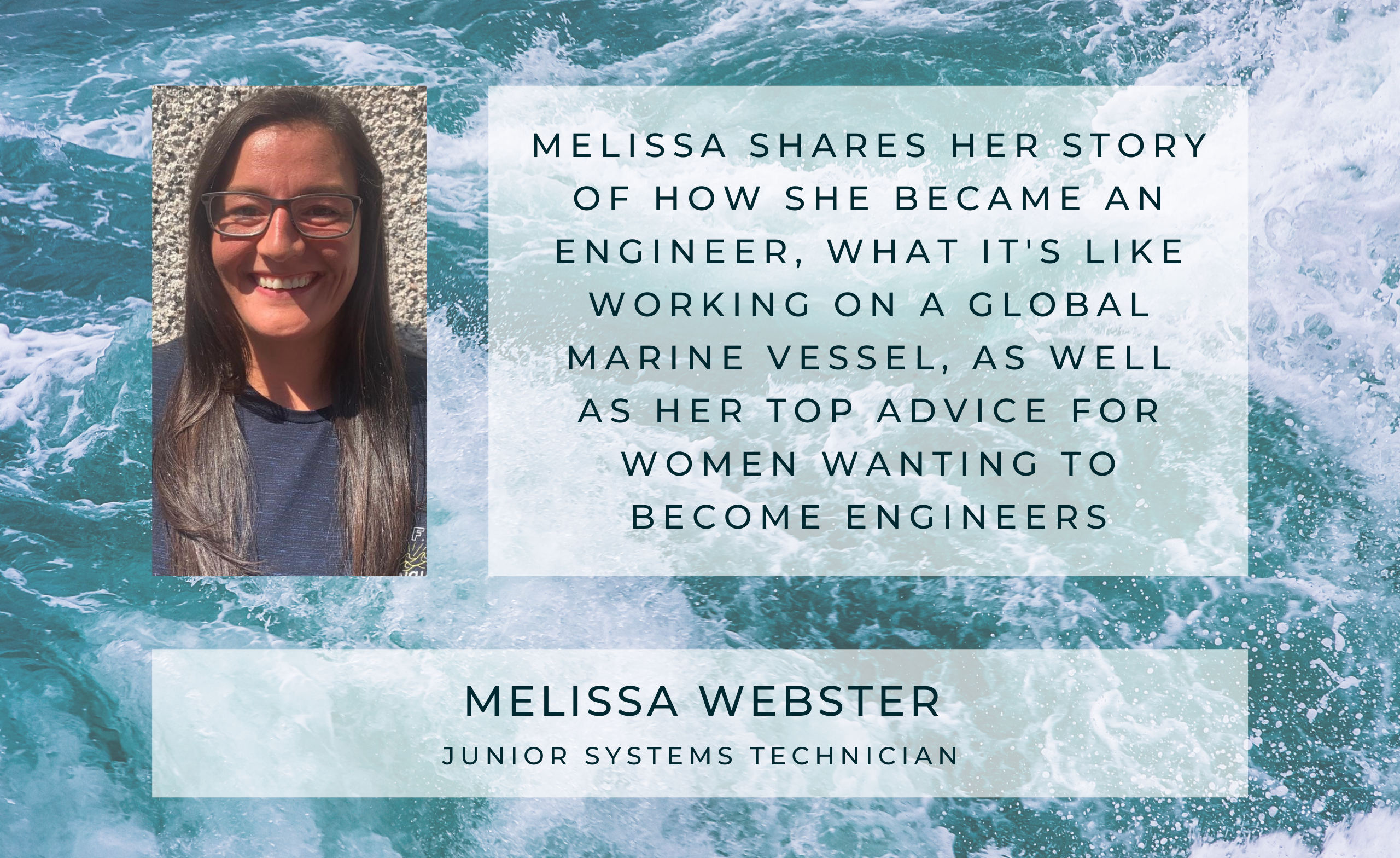

Junior Systems Technician We recently spoke to Melissa Webster, a Junior Systems Technician on...

Five-Year Extension Runs to End of 2025 Global Marine, a leading provider of subsea...

To mark the IMO Day of the Seafarer 2021 we spoke to two of...

Global Marine has been awarded the desktop study, survey and cable installation scope as...

In recognition of the high standard of weather observations undertaken voluntarily at sea Global...

Global Marine Group, along with over 450 other organiations have joined forces to help...

The Atlantic Cable Maintenance Agreement (ACMA) members and their suppliers Global Marine and Orange...

The United Nation’s World Maritime Day held at the end of September shone a...

Global Marine Group (GMG) a leading provider of subsea cable installation and maintenance services...

Global Marine, a leading provider of subsea fibre optic cable installation and maintenance solutions...

We’re pleased to share this exciting press release from SEA-KIT celebrating the return of...

We recently celebrated our annual awards to recognise some of the shining stars within...

Today marks what should have been the graduation ceremony for students from the City...

As part of the wider Global Marine business, our UJ team are quite unique...

During subsea fibre optic cable repairs, universal joints (UJ) are used to reconnect damaged...

As the COVID-19 pandemic continues to affect businesses and individuals globally, like everyone, we’ve been adapting...

In light of recent developments and UK Government guidelines, we wanted to update our...

Global Marine Group (“GMG” or the “Company”), a leading provider of subsea cable installation...

The Global Marine Group is extremely pleased to announce that an agreement has been...

Global Marine Group (GMG), supported by its business units Global Marine, Global Offshore and...

In 2019, the focus of International Women’s Day is about balance. Balance drives a...

Osbit Limited, the offshore technology and engineering company, has secured a contract with Global...

Global Marine, a market leader in subsea fibre optic cable installation and maintenance solutions...

Global Marine Group has been issued a prestigious award in recognition of its practices...

For the last couple of weeks, Megan, an A level student from Great Baddow...

Next week, a team of amateur and enthusiastic riders from Global Marine, CWind and...

At the end of June we held our Annual Awards Evening recognising employees and...

Ian Douglas Wins CEO Today Magazine European Awards We are pleased to officially announce...

Global Offshore is pleased to share Scottish & Southern Electricity Networks’ latest press release regarding a...

The Global Marine Group (GMG), a market leader in offshore engineering services to the...

The Global Marine Group (GMG), a market leader in offshore engineering services to the...

Acquisition Further Positions Global Marine Group for Significant Offshore Power Market Opportunities Chelmsford, Friday...

Global Marine Group (GMG) has launched a new Safety, Security and Environmental Management System...

Acquisition further positions company for significant offshore power market opportunities Chelmsford, Thursday 12 October...

Chelmsford, Tuesday 5 September 2017. The Global Marine Group (GMG), a market leader in offshore...

Chelmsford, Thursday 31 August 2017. The Global Marine Group (GMG), a market leader in offshore...

| Cookie | Duration | Description |

|---|---|---|

| bcookie | 2 years | LinkedIn sets this cookie from LinkedIn share buttons and ad tags to recognize browser ID. |

| lang | session | This cookie is used to store the language preferences of a user to serve up content in that stored language the next time user visit the website. |

| lidc | 1 day | LinkedIn sets the lidc cookie to facilitate data center selection. |

| __atuvc | 1 year 1 month | AddThis sets this cookie to ensure that the updated count is seen when one shares a page and returns to it, before the share count cache is updated. |

| __atuvs | 30 minutes | AddThis sets this cookie to ensure that the updated count is seen when one shares a page and returns to it, before the share count cache is updated. |

| __cf_bm | 30 minutes | This cookie, set by Cloudflare, is used to support Cloudflare Bot Management. |

| __hssc | 30 minutes | HubSpot sets this cookie to keep track of sessions and to determine if HubSpot should increment the session number and timestamps in the __hstc cookie. |

| Cookie | Duration | Description |

|---|---|---|

| hubspotutk | 1 year 24 days | This cookie is used by HubSpot to keep track of the visitors to the website. This cookie is passed to Hubspot on form submission and used when deduplicating contacts. |

| uvc | 1 year 1 month | Set by addthis.com to determine the usage of addthis.com service. |

| vuid | 2 years | Vimeo installs this cookie to collect tracking information by setting a unique ID to embed videos to the website. |

| _ga | 2 years | The _ga cookie, installed by Google Analytics, calculates visitor, session and campaign data and also keeps track of site usage for the site's analytics report. The cookie stores information anonymously and assigns a randomly generated number to recognize unique visitors. |

| _gat_UA-47160345-1 | 1 minute | A variation of the _gat cookie set by Google Analytics and Google Tag Manager to allow website owners to track visitor behaviour and measure site performance. The pattern element in the name contains the unique identity number of the account or website it relates to. |

| _gid | 1 day | Installed by Google Analytics, _gid cookie stores information on how visitors use a website, while also creating an analytics report of the website's performance. Some of the data that are collected include the number of visitors, their source, and the pages they visit anonymously. |

| __hstc | 1 year 24 days | This is the main cookie set by Hubspot, for tracking visitors. It contains the domain, initial timestamp (first visit), last timestamp (last visit), current timestamp (this visit), and session number (increments for each subsequent session). |

| Cookie | Duration | Description |

|---|---|---|

| bscookie | 2 years | This cookie is a browser ID cookie set by Linked share Buttons and ad tags. |

| loc | 1 year 1 month | AddThis sets this geolocation cookie to help understand the location of users who share the information. |

| Cookie | Duration | Description |

|---|---|---|

| AnalyticsSyncHistory | 1 month | No description |

| at-rand | never | No description available. |

| li_gc | 2 years | No description |

| MBPe5d0990ce6654bb1a50eb8000bb9f3f0 | 3 years | No description |

| UserMatchHistory | 1 month | Linkedin - Used to track visitors on multiple websites, in order to present relevant advertisement based on the visitor's preferences. |

| xtc | 1 year 1 month | No description |