The Global Marine Group is pleased to announce the new ownership of the business by Keppel Infrastructure Fund, a fund managed by Keppel.

Contact Us

Home » Our Markets » Oil & Gas

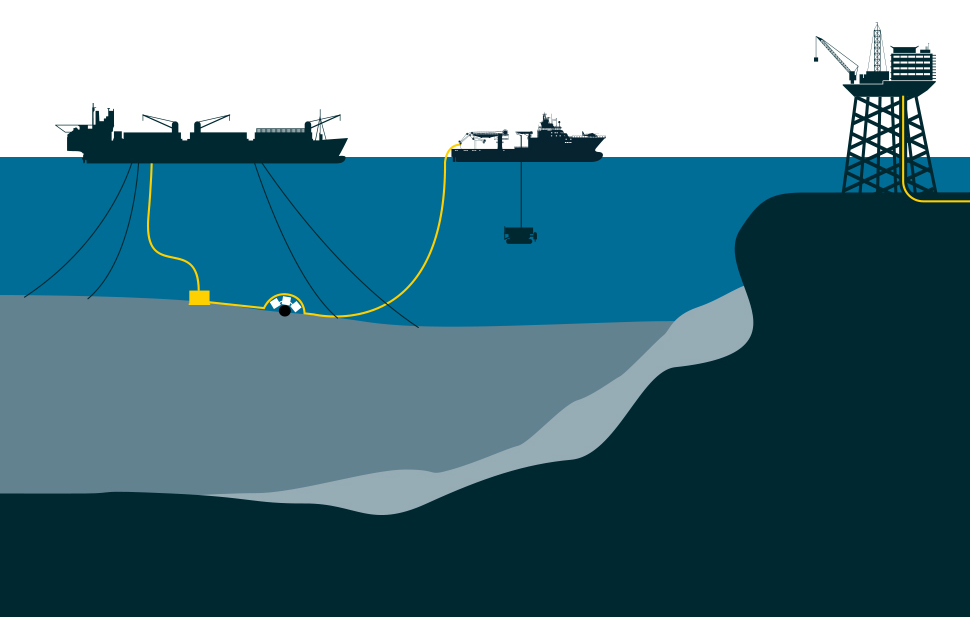

With an extraordinary history in delivering subsea projects Global Marine is in a prime position to offer a wide variety of innovative cabling and trenching solutions to the oil & gas sector.

Global Marine has extremely capable and knowledgeable people, vessel capability and the subsea equipment available to provide installation and engineering services for platform-to-platform connectivity and complete platform to shore installation services.

As a total subsea solution provider, Global Marine offers a proven step-by-step approach for the life of a subsea cable system.

The Global Marine Group fleet has a successful track record of project delivery for oil & gas customers.

Broadband data networks are rapidly emerging as the most effective technology to support diverse advances in oil field management, and are installed to manage risk, supervise remote drilling operations and using real-time information to drive field economies.

Have an enquiry Global Marine can help you with? Complete the contact form and one of our experts will be in touch shortly.

Widely considered as subsea cable experts, Global Marine has delivered comprehensive end-to-end solution on a diverse range of projects in the oil and gas sector.

North Sea Gas Major. Hybrid trenching on 3km flexible glowline and installation & burial of 6km umbilical. Vessel: Global Symphony – Location: North Sea

Quad 204. Installation of new subsea infrastructure. Vessel: Global Symphony – Location: North Sea

Golden Eagle. Umbilical installation. Vessel: Global Symphony – Location: North Sea

Tampnet MCCS, North Sea. Lay and burial of 36km fibre optic cable with CEM deployment. Vessel: C.S. Sovereign – Client: Tampnet

Tampnet 4, North Sea. 74km inter-platform connectivity, including 4 branching units and mattress work. Vessel: Innovator – Client: Tampnet

Tampnet 3, North Sea. Installation of 87km of FOC between three platforms incorporating the deployment of three branching units. Vessel: Innovator – Client: Tampnet

PNG Lng Foc, Papua New Guinea. Lay & burial of 71km fibre optic cable. Vessel: Networker – Client: Saipem

Breagh A, UK. 104 km plough burial of shore to platform fibre optic cable. Vessel: Innovator – Client: Allseas

Fibre to Judy, UK. 30km ROV burial of inter platform cable. Vessel: Sovereign – Client: NSC

Valhall to Clyde, UK. 110km of plough burial between two platforms using the Super Mowhawk and Hi-Plough. Vessel: Sovereign – Client: NSC

Norne to Bronnoysund, Norway. 252km plough burial, shore to platform cable installation. Vessel: Sentinel – Client: Statoil

| Cookie | Duration | Description |

|---|---|---|

| bcookie | 2 years | LinkedIn sets this cookie from LinkedIn share buttons and ad tags to recognize browser ID. |

| lang | session | This cookie is used to store the language preferences of a user to serve up content in that stored language the next time user visit the website. |

| lidc | 1 day | LinkedIn sets the lidc cookie to facilitate data center selection. |

| __atuvc | 1 year 1 month | AddThis sets this cookie to ensure that the updated count is seen when one shares a page and returns to it, before the share count cache is updated. |

| __atuvs | 30 minutes | AddThis sets this cookie to ensure that the updated count is seen when one shares a page and returns to it, before the share count cache is updated. |

| __cf_bm | 30 minutes | This cookie, set by Cloudflare, is used to support Cloudflare Bot Management. |

| __hssc | 30 minutes | HubSpot sets this cookie to keep track of sessions and to determine if HubSpot should increment the session number and timestamps in the __hstc cookie. |

| Cookie | Duration | Description |

|---|---|---|

| hubspotutk | 1 year 24 days | This cookie is used by HubSpot to keep track of the visitors to the website. This cookie is passed to Hubspot on form submission and used when deduplicating contacts. |

| uvc | 1 year 1 month | Set by addthis.com to determine the usage of addthis.com service. |

| vuid | 2 years | Vimeo installs this cookie to collect tracking information by setting a unique ID to embed videos to the website. |

| _ga | 2 years | The _ga cookie, installed by Google Analytics, calculates visitor, session and campaign data and also keeps track of site usage for the site's analytics report. The cookie stores information anonymously and assigns a randomly generated number to recognize unique visitors. |

| _gat_UA-47160345-1 | 1 minute | A variation of the _gat cookie set by Google Analytics and Google Tag Manager to allow website owners to track visitor behaviour and measure site performance. The pattern element in the name contains the unique identity number of the account or website it relates to. |

| _gid | 1 day | Installed by Google Analytics, _gid cookie stores information on how visitors use a website, while also creating an analytics report of the website's performance. Some of the data that are collected include the number of visitors, their source, and the pages they visit anonymously. |

| __hstc | 1 year 24 days | This is the main cookie set by Hubspot, for tracking visitors. It contains the domain, initial timestamp (first visit), last timestamp (last visit), current timestamp (this visit), and session number (increments for each subsequent session). |

| Cookie | Duration | Description |

|---|---|---|

| bscookie | 2 years | This cookie is a browser ID cookie set by Linked share Buttons and ad tags. |

| loc | 1 year 1 month | AddThis sets this geolocation cookie to help understand the location of users who share the information. |

| Cookie | Duration | Description |

|---|---|---|

| AnalyticsSyncHistory | 1 month | No description |

| at-rand | never | No description available. |

| li_gc | 2 years | No description |

| MBPe5d0990ce6654bb1a50eb8000bb9f3f0 | 3 years | No description |

| UserMatchHistory | 1 month | Linkedin - Used to track visitors on multiple websites, in order to present relevant advertisement based on the visitor's preferences. |

| xtc | 1 year 1 month | No description |